CATEGORIES

- Aluminum Sheet/Plate

- Aluminum Coil

- Aluminum Strip

- Aluminum Foil

- Aluminum Discs/Circle

- Aluminum Slugs

- Aluminum Tread Plate

- Aluminum Profile

- Color Coated Aluminium

- CTP Plates

LATEST NEWS

- Aluminum Coil Stock For Gutters

- PVDF Painted Aluminium Sheet

- Polyester Coated Aluminium Sheet

- Coated Aluminum Coil For Gutters

- Coloured Aluminium Sheet Thickness

- Powder Coated Aluminum Sheet

CONTACT US

- ADD: 1103 No.14 Shangwu Outer Ring Rd, New District, Zhengzhou, China.

- TEL: 86-371-65621391

- FAX: 86-371-65621393

- E-mail: nydia@aluminumhm.com

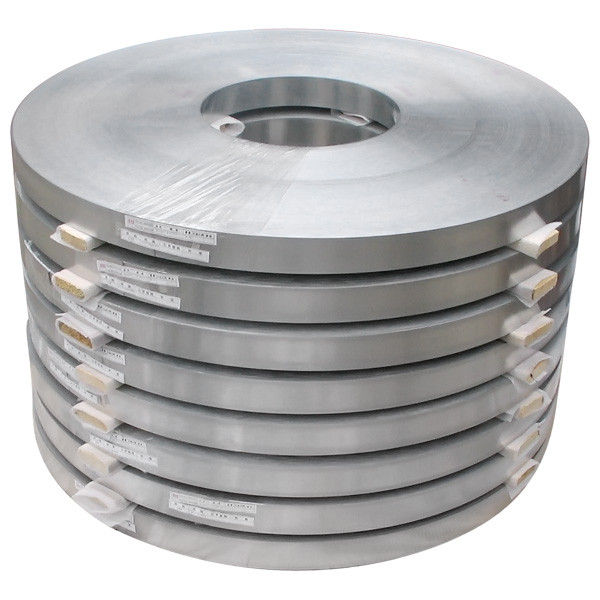

Auto Condenser Aluminium Foil Roll

- Brand:haomei

- Product description: Quality auto condenser Aluminium Foil Roll manufacturers & exporter - Haomei aluminum are willing to service for you.

PRODUCT INTRODUCTION

| Core Alloy: | 3003+1.5%Zn | Clad Alloy: | 4343 |

|---|---|---|---|

| Thickness: | 0.08mm | Width: | 16mm |

| I.D.: | 254mm | O.D.: | ≤1135mm |

| Packaging: | Eye To Sky / Wall | Temper: | H14 |

0.08 x 16mm 4343 / 3003+1.5%Zn / 4343 H14 Aluminum Cladded Foil Roll for Auto Condenser

1. Description of our production

Chemical composition of core material, cladding material about aluminum alloy and composite-material for welding heat exchanger

1) Core Material

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Zr | Ti | code |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | 0.1 | 0.05 | 0.03 | 1 |

| 3003+1%Zn | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | 0.5-1.50 | 0.05 | 0.05 | 2 |

| 3003+1.5%Zn | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | 1.0-2.0 | 0.05 | 0.05 | 3 |

| 3003+1.5%Zn+Zr | 0.5-1.0 | 0.7 | 0.05-0.20 | 1.0-1.6 | - | 1.0-2.0 | 0.05-0.2 | – | 4 |

| 3003+0.5%Cu | 0.6 | 0.7 | 0.30-0.70 | 1.0-1.5 | - | 0.10 | 0.05 | 0.1 | 5 |

| 3005 | 0.6 | 0.7 | 0.20-0.40 | 1.0-1.5 | 0.20-0.60 | 0.25 | - | 0.01 | 6 |

2) Cladding Material

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Zr | Ti | code |

| 4343 | 6.8-8.2 | 0.8 | 0.25 | 0.1 | - | 0.2 | - | 0.05 | 1 |

| 4343+1%Zn | 6.8-8.2 | 0.8 | 0.25 | 0.1 | - | 0.5-1.5 | - | 0.05 | 2 |

| 4045 | 9.0-11.0 | 0.8 | 0.3 | 0.05 | - | 0.2 | - | 0.2 | 3 |

| 4045+1%Zn | 9.0-11.0 | 0.8 | 0.3 | 0.05 | - | 0.5-1.5 | - | 0.2 | 4 |

| 4004 | 9.0-10.5 | 0.8 | 0.25 | 0.1 | 1.0-2.0 | 0.2 | - | 0.2 | 5 |

| 7072 | 0.7 | 0.1 | 0.1 | 0.1 | 0.8-1.3 | - | - | 6 | |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.5-1.0 | - | 0.03 | 7 |

3) Main mechanical of aluminum alloy and composite-material for welding heat exchanger

| Alloy Code | temper |

Tensile Strength

Rm(MPa) |

Yield Strength Rp0.2(Mpa) |

Extend Ratio

A50(%) |

|

TR-010,TR-020,TR-030,TR-040,TR-050,TR-110,TR-310, TR-116,TR-316,TR-111,TR-313,TR-121,TR-131,TR-141, TR-150,TR-151,TR-156 Etc. |

O | 95-135* | ≥35* | ≥15* |

| H14 | 140-185 | ≥125 | ≥1.5 | |

| H24 | 140-185 | ≥125 | ≥3.0 | |

| H16 | 185-225 | ≥160 | ≥1.0 | |

| H18 | ≥185 | – | ≥0.5 | |

| TR-166 Etc.tube material | H24 | 185-235 | ≥150 | ≥8 |

|

TR-116,TR-316 Etc.tube

material |

H14 | 140-185 | ≥125 | ≥3 |

| H24 | 140-185 | ≥125 | ≥8 |

Remark:“*”in the above file means the tensile strength will be 120-150Mpa,yield strength will be ≥45Mpa,and elongation will be ≥20% if the material of TR-050,TR-150,TR-151,TR-156 etc. with temper O contain Cu..

Additional: We can produce special specification according to customer’s request.

4) Produce capability

| Width(mm) | Thickness(mm) | Length(mm) | Inside Diameters(mm) | |

| Sheet | 500-1070 | 0.5-5.0 | 500-2500 | – |

| Strip | 12-1070 | 0.2-3.0 | – | 150,200,300,400,500 |

| Foil | 12-1070 | 0.05-0.2 | – | 150,200,300,400,500 |

| Composite ratio | 4-18%(per side) |

| Percent Clad(per side) | 4-8% | > 8-18% |

| Cladding tolerance | ±1.5% | ±2.0% |